This birch log was filched from Reid and Jewell Hausmann’s driveway right after it was cut and then ripped in half with the chainsaw:

Half log was mounted with the faceplate and the center determined and then trimmed to almost round on the bandsaw, as described below in an earlier post.

It was then remounted and turned

It was rough turned

(and was so wet it sprayed water/sap on the floor of the shop)

The outside of the bowl shaped and a tenon turned on the bottom and then

reverse mounted in the 4-jaw chuck

reverse mounted in the 4-jaw chuck

and then hollowed out, leaving about 10% of its width.

and then hollowed out, leaving about 10% of its width.

The wet wood makes these nice, long, linguini-like shavings.

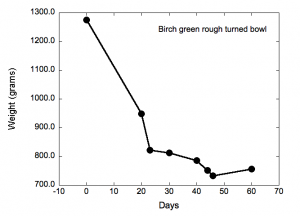

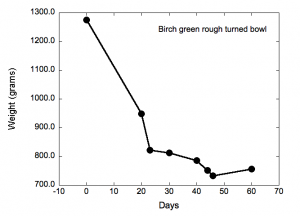

After rough turning, the bowl was put up to dry for a few months. I have weighed it and will follow the drying by re-weighing it from time to time until its weight levels off.

When it is dry enough, it will be turned to its final shape and thickness.

After 60 days of spending time in the basement (high humidity) or upstairs (lower humidity) and a couple shots in the microwave on day 44, and then back to the basement on day 46, the weight seems to have stabilized around 750 grams, having started at a little less that 1300 grams:

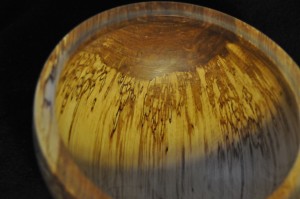

After drying for 60 days:

The bowl has cracked a little around the pith on the far side; so the top edge will have to be turned down below that point.

For the final result see June 3, 2012